Why Us

OUR ADVANTAGE

better, faster and more economically.

CUSTOM MOULDS

Various mold types, integrated design and development.

design

Professional design team, integrated R&D.

FREE SAMPLES

Various free cosmetic packaging samples.

AFTER-SERVICE

One-stop after-sales service to solve technical problems.

Established in

workers

Production Bases

US&UK Patented Designs

Factory

Five major factories

LISSON Group is a group enterprise dedicated to providing customers with complete sustainable and environmentally friendly packaging solutions.

1 1

Cosmetic Tubes Plant

Plastic Tube plant area is more than 20,000 square meters, with 400 employees, 10 tube production lines and 6 laminated tube production lines. Possess production equipment: 10 tube drawing machines, 22 head injection machines, 11 printing machines, 10 silk screen printing machines, 6 hot stamping machines, 9 tail sealing machines, 9 lock cover film laminating machines, 1 sub-mother assembly machine, 3 labeling machines.

1 1

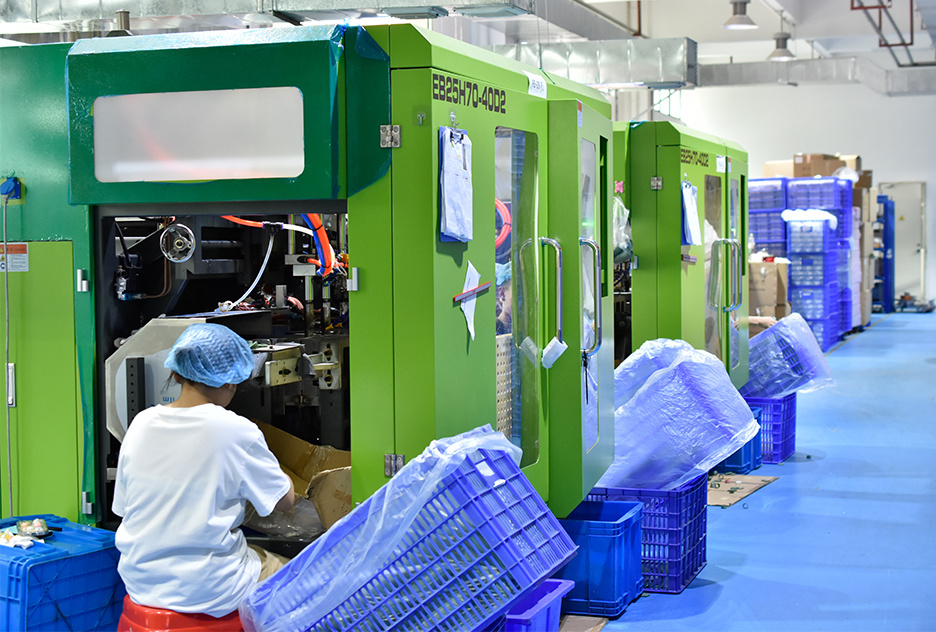

Plastic Bottles Plant

LISSON Plastic Bottle factory covers an area of more than 3000 square meters, employs 80 people, and has 3 plastic bottle production lines. Owned equipment: 5 PE blow molding machines, 3 PET blow molding machines, 8 silk screen printing machines, with a monthly effective production capacity of 5 million sets. With modern production technology and experienced technical management team, we can provide customers with customized development services.

1 1

Aluminum Tubes Plant

The plant covers an area of more than 17,500 square meters, employs 130 people, and has 10 fully automatic aluminum tube production lines imported from Germany. The monthly effective production capacity is 20 million sets. It mainly produces aluminum tubes with a diameter of 11mm~40mm and a capacity of 10ml~200ml. The products are mainly used in pharmaceuticals, cosmetics, hair dyeing and hair care, chemicals, food jams and other related fields.

1 1

Aluminum Bottles&Jars Plant

Lisson Aluminum Bottles & Jars plant covers an area of more than 8,000 square meters, employs 82 people, and has 3 automatic aluminum bottle production lines. Owned equipment: 3 die-casting machines, 5 punching machines, 21 CNC necking machines, 5 threading machines, 1 CNC lathe, 1 mechanical lathe, 1 set of cleaning pools, 5 large and small ovens, 3 spraying machines, 1 Set of polishers. 1 painting line, 1 packer, 5 printing machines. 1 set of film machine. 2 sets of air compressors, the monthly effective production capacity is 3 million sets.

1 1

Mold Plant

The Mold factory covers an area of more than 8,000 square meters, with 70 employees, 25 injection molding machines, and more than 600 sets of molds for the production of cosmetic packaging plastic covers; currently, the plastic covers that can be produced include mother-in-law covers, vibrating eye cream covers, ball cover, double-layer Combination caps, anodized aluminum caps, acrylic caps, ordinary flip caps (flip caps) screw caps and various functional caps. Support proofing, support drawing processing, sample processing.

products

FEATURED PRODUCTS

LISSON Group is a group enterprise dedicated to providing customers with complete sustainable and environmentally friendly packaging solutions.

News

Company news

LISSON Group is a group enterprise dedicated to providing customers with complete sustainable and environmentally friendly packaging solutions.

cooperation

our Business partner

LISSON Group is a group enterprise dedicated to providing customers with complete sustainable and environmentally friendly packaging solutions.

Contact us

get in touch with us

If you need help, please enter what you want to consult, then enter your mobile phone number to get the verification code, click Submit.